Modern Prefabricated Homes Built for Practical and Comfortable Living

Prefabricated homes have become a popular choice for people seeking a practical living solution that combines efficiency with thoughtful design. In Ukraine, these homes are appreciated for their structured building process and the flexibility they offer in layout and style. Many families value the stability and comfort provided by modern materials and well-planned construction methods. With clear design options and reliable building practices, prefabricated homes make it easier to create a living space that fits everyday needs while offering a balanced and organized environment.

Prefabricated housing represents a significant shift in residential construction, where major components are manufactured in controlled factory settings before being transported and assembled on-site. This approach reduces construction timelines while maintaining structural integrity and design flexibility. Modern prefabricated homes cater to diverse preferences, from compact single-family residences to larger multi-story structures, all while emphasizing quality materials and thoughtful spatial planning.

How Does the Prefabricated Construction Process Work?

The prefabricated construction process begins with detailed planning and design phases where architects and engineers create specifications tailored to client requirements and local building codes. Manufacturing facilities then produce wall panels, floor systems, roof trusses, and other components under controlled conditions that minimize weather-related delays and material waste. Quality control inspectors monitor each production stage to ensure components meet structural standards.

Once manufacturing completes, transportation logistics coordinate delivery of sections to the building site where foundation work has been prepared. Assembly crews connect the prefabricated modules or panels according to engineering plans, typically completing the shell structure within days rather than months. Electrical systems, plumbing, insulation, and interior finishes follow, with many elements pre-installed during factory production. This systematic approach reduces on-site labor requirements and accelerates occupancy timelines compared to conventional building methods.

What Defines Modern Home Design in Prefabricated Construction?

Modern home design in prefabricated construction emphasizes clean architectural lines, open floor plans, and efficient use of interior space. Large windows and strategic placement of natural light sources create bright living environments while reducing energy consumption. Contemporary prefabricated homes often incorporate sustainable features such as energy-efficient insulation, solar panel compatibility, and water conservation systems.

Design flexibility allows customization of layouts, exterior finishes, and interior materials to match personal aesthetics and functional requirements. Modular configurations enable homeowners to select room arrangements that accommodate family size, work-from-home needs, or accessibility considerations. Manufacturers offer various style options ranging from minimalist Scandinavian influences to more traditional architectural elements, ensuring prefabricated homes integrate visually with surrounding neighborhoods.

What Practical Living Solutions Do Prefabricated Homes Offer?

Practical living solutions in prefabricated homes address real-world challenges facing modern homeowners. Efficient construction timelines mean families can move into completed residences faster, reducing temporary housing costs and relocation stress. Factory-controlled production minimizes construction defects and ensures consistent quality across all building components.

Space optimization features maximize usable square footage through intelligent storage solutions, multi-functional rooms, and thoughtful circulation patterns. Energy-efficient designs lower utility expenses through superior insulation, high-performance windows, and modern HVAC systems. Many prefabricated homes also accommodate future expansion, allowing homeowners to add modules or sections as family needs change without major structural renovations.

Which Reliable Building Materials Are Used in Prefabricated Construction?

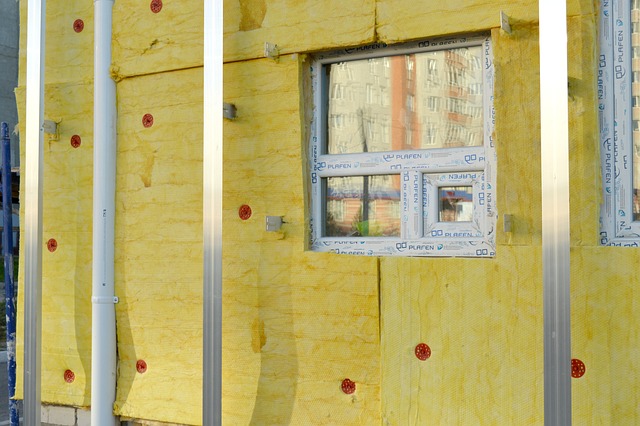

Reliable building materials form the foundation of quality prefabricated homes, with manufacturers selecting components based on durability, structural performance, and environmental impact. Engineered wood products, steel framing systems, and reinforced concrete provide structural integrity while meeting international building standards. These materials undergo rigorous testing to ensure they withstand regional climate conditions, seismic activity, and long-term wear.

Exterior cladding options include fiber cement panels, metal siding, brick veneer, and treated wood that resist moisture damage and require minimal maintenance. Insulation materials such as mineral wool, spray foam, or rigid foam boards provide thermal efficiency and soundproofing. Interior finishes utilize low-VOC paints, durable flooring materials, and moisture-resistant drywall that contribute to healthy indoor air quality. Manufacturers increasingly source sustainable and recycled materials to reduce environmental footprints while maintaining construction standards.

Cost Considerations for Prefabricated Homes

Understanding the financial aspects of prefabricated construction helps prospective homeowners make informed decisions. Costs vary significantly based on design complexity, size, material selections, and site preparation requirements. Basic prefabricated homes typically start at more accessible price points compared to custom-built traditional homes, though premium designs with advanced features command higher investments.

| Home Type | Size Range | Estimated Cost Range |

|---|---|---|

| Basic Modular Home | 60-100 sqm | $30,000 - $60,000 |

| Standard Prefab Home | 100-150 sqm | $60,000 - $120,000 |

| Premium Prefab Home | 150-200 sqm | $120,000 - $200,000 |

| Luxury Custom Prefab | 200+ sqm | $200,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Additional expenses include land acquisition, foundation work, utility connections, site preparation, transportation, and assembly labor. Financing options for prefabricated homes have expanded as lenders recognize their value and durability, though terms may differ from traditional mortgage products. Homeowners should budget for permits, inspections, and potential customization costs when planning their prefabricated home projects.

Long-Term Benefits and Considerations

Prefabricated homes offer long-term advantages that extend beyond initial construction savings. Reduced building waste during factory production contributes to environmental sustainability, while energy-efficient designs lower ongoing utility costs. Maintenance requirements typically align with traditional homes, though quality materials and precise factory construction may reduce repair frequencies.

Resale values for prefabricated homes have improved as market acceptance grows and construction quality becomes more widely recognized. Proper site selection, foundation work, and professional installation significantly impact long-term performance and property value. Homeowners should verify that their prefabricated homes meet local building codes and zoning regulations to ensure compliance and future marketability.

Prefabricated construction continues evolving with technological advances in manufacturing, materials science, and sustainable building practices. These homes provide viable solutions for those seeking efficient construction timelines, modern design aesthetics, and practical living environments. As the housing industry adapts to changing demands, prefabricated options represent a practical approach to residential construction that balances quality, affordability, and environmental responsibility.